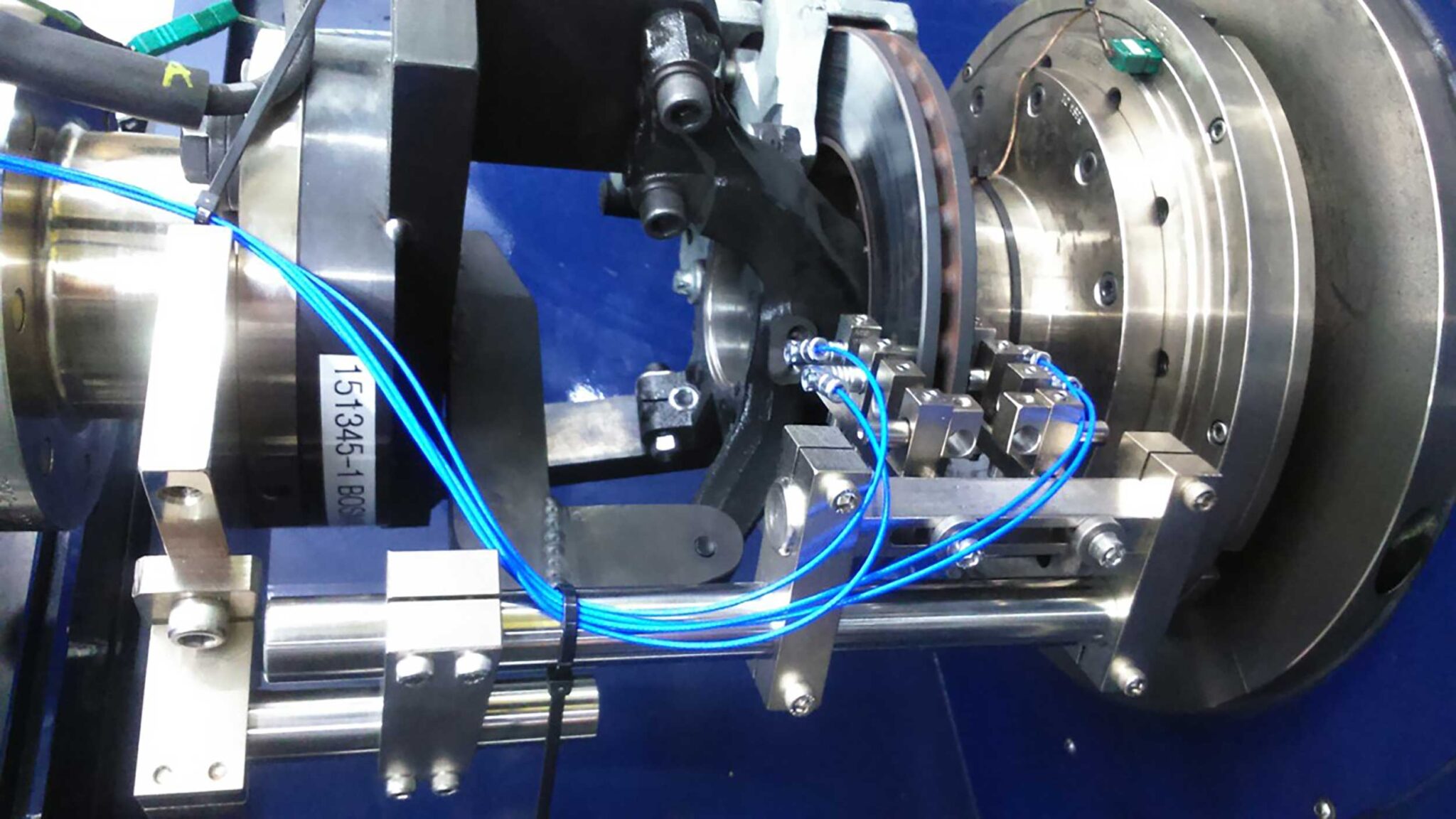

Power Brake’s Diamond Technology was tested by Greening Testing Laboratories, Inc. according to SAE J2115.

Power Brake has met the requirements of the Federal Motor Vehicle Safety Standards (FMVSS) 121 – Section 6 SAE J2115.

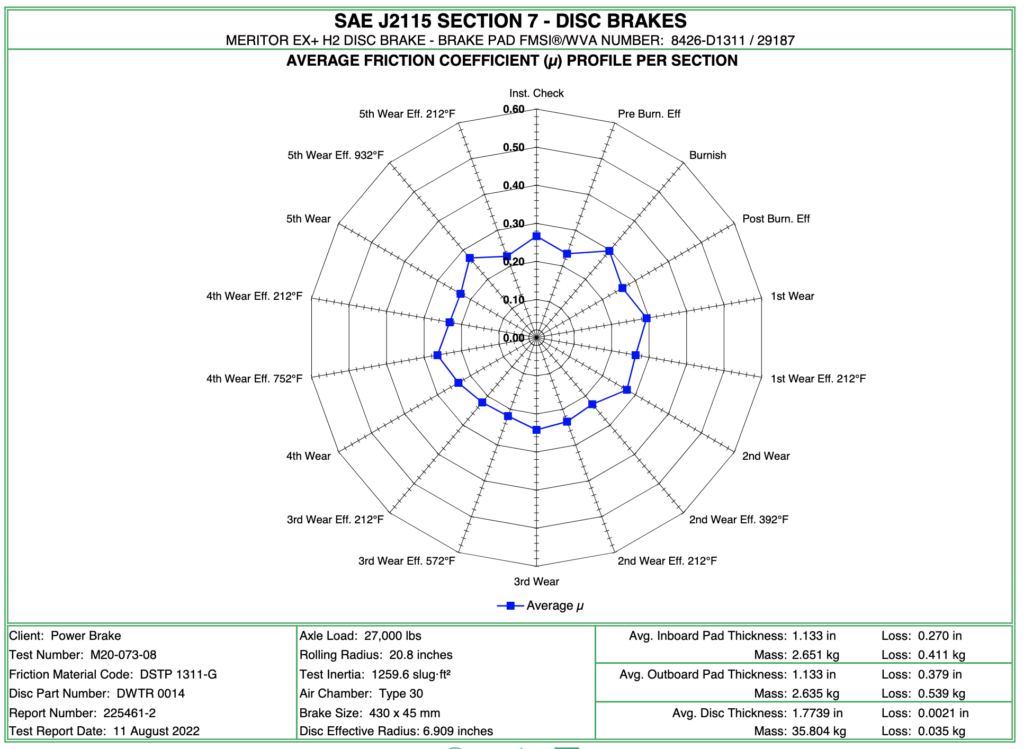

Section 7 covers Wear & Effectiveness at Temperature Version. This test is conducted to confirm wear rates and brake effectiveness of the disc rotor and the brake pads friction coupler at 5 different temperature cycles.

5,265 cycles were conducted, with a maximum temperature of 1,222 F that was reached during the 5th cycle. The results were impressive; Most rotors and pads wear out completely, but our rotors wore less than 1mm and the pads only wore about halfway.

| Brake Pad Wear Rate Average | Thickness Loss – 0.649” Mass Loss Kg – 0.950 Kg. | |

| Brake Disc Rotor Wear Rate Average | Thickness Loss – 0.0021” Mass Loss Kg – 0.035 Kg. | |

| Post Visual Inspection of Brake Pads | No Flaking Light Glazing Light Grooving Light Pitting Light Resin Bleed No Cracking | |

| Post Visual Inspection of Brake Disc Rotor | No Heat Checking No Hot Spots Light Grooving No Cracking Light Lining Transfer Brown, Grey in Color | |

| Surface Finish of Brake Disc Rotor | 42 Ra Start 98 Ra Finish TIR (total indicated runout) 0.002” | |

| Brake Friction Coefficient Frequenc | 0.20 Stage – Post Burnish was 2.5% 0.32 Stage – 100% From Post Burnish through Completion – No Frequency in Friction |

The graph below shows the stability of the coefficient of friction throughout the entire test, hot or cold braking